When buying a UVLED curing machine, the most important factor to consider is not the price, but whether this UVLED curing

machine is suitable for your company's products and whether it can meet the requirements of your product production depends

on your product’s production process, capacity, Glue energy requirements, choose a UVLED curing machine suitable for your use.

Especially for UVLED curing machine, because of its many types, you must understand their performance and professional use in

detail, so that the equipment you buy can play its best role.

If you are in contact with and buying a UVLED curing machine for the first time, before buying a UVLED curing machine, you

may have some questions about what kind of UVLED curing machine you need. What kind of UVLED curing machine is more

suitable for us? As a UVLED curing machine manufacturer,Height-LED recommends that you consider three aspects: production

process, production efficiency and curing effect.

1. Production process

When choosing a UVLED curing machine, you need to make a choice based on the problems of your existing production process.

For example, it is TP laminating process, then we need to determine whether we use UVLED curing machine for pre-curing or primary

curing, whether it is used for side fixation or surface fixation. Determine the production process, the target size of curing, and the

parameters of the glue, and then we will choose the UVLED curing machine.

2. Production efficiency

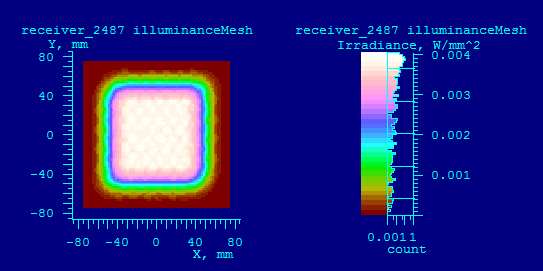

This is the key indicator for choosing a UVLED curing machine, because the level of production efficiency will determine one of

the core parameters of the UVLED curing machine-radiation energy. If the production efficiency is high, then the required radiation

illuminance is higher. For example, your process requires 2000mJ of UV energy to complete the curing of the glue, and the

irradiation time of the UVLED curing machine must be within 5S, then the radiation illuminance of the UVLED curing machine you

choose must be greater than or equal to 2000mJ÷5s=400mW/cm2.

Of course, before considering this, you have to know which UV wavelength is used to irradiate the UV glue or UV ink used in your

production process. Conventional UVLED curing machines have different wavelengths such as 365nm, 395nm, 405nm and so on. In

addition, It is the UV radiation energy required for the complete curing of glue or ink. For this, you need to consult your UV glue or

UV ink supplier.

3. Curing effect

The parameters marked by many manufacturers are very different, and they don't know much about UVLED curing machines.

Actually seeing the test results is the most fundamental. You can send your glue or ink, as well as samples, to Shenzhen Height-LED

for testing. For more than ten years, the company has customized countless UVLED curing machines for various industries and

accumulated rich experience. I believe that after testing, you can find a cost-effective solution that suits your company's products.