UVLED light curing technology has developed rapidly, and has also been widely used in the printing industry. UVLED light curing

has gradually replaced the position of traditional mercury lamps on printing presses.

Flexo printing is a type of relief printing. It is a wheel-shaped letterpress printing that uses soft, elastic rubber plates or

elastomer plates to print. Flexo printing was first used in 1890. At that time, rubber was used as a plate, and the development was

slow. It was not until the emergence of photosensitive resin flexo in 1970 that greatly improved the speed and precision of plate

making. Flexo printing entered a new period of development. The flexo printing process has wide applicability and can be applied to

different substrate materials. In addition to traditional paper, some non-absorbent printing materials such as cellophane, plastic

film, plastic products, metal foil, glass products, etc. Can be printed on corrugated paper.

The UVLED curing light source installed on the flexo printing machine has the following advantages:

1. Install uvled curing light source, no preheating is needed for starting, it can be used immediately after starting, and the

maximum power output can be reached after starting, which is convenient and fast.

2. The uvled curing light source has a long service life, which can generally reach 20,000 hours, which is 20 times that of traditional

mercury lamps.

3. It can be restarted immediately after shutdown, the number of switches does not affect the life of the light source.

4. The uvled curing light source is a cold light source UV, with low temperature and high energy, stable light output, good uniform

illumination effect, and improved production efficiency.

5. No mercury, no harmful substances of heavy metals, no ozone, safety, environmental protection and energy saving.

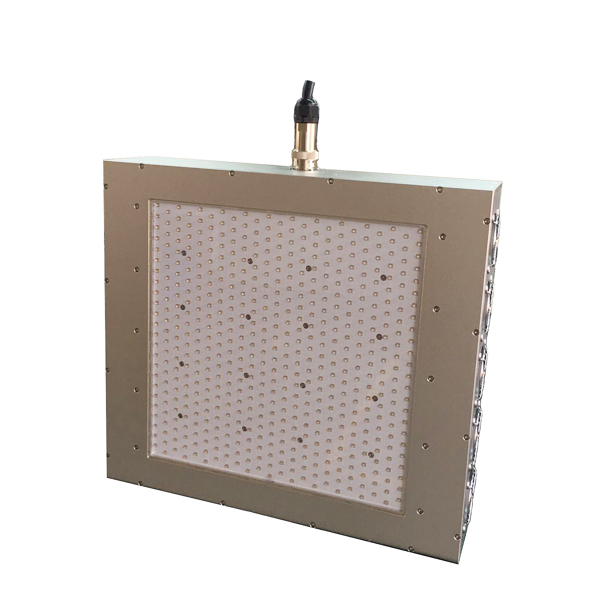

Height-LED specializes in the development and production of uvled curing light sources. It uses imported lamp beads and is designed

and installed by professionals. The product quality is guaranteed and trustworthy.