UV flexo inks and their process technology are constantly improving and improving,

and new varieties and new equipment are also emerging. All of this will promote the

perfection of UV flexo printing technology. Undoubtedly, the development prospect

of UV flexo printing technology is very good. UV flexo technology applications

need to pay attention to some problems.

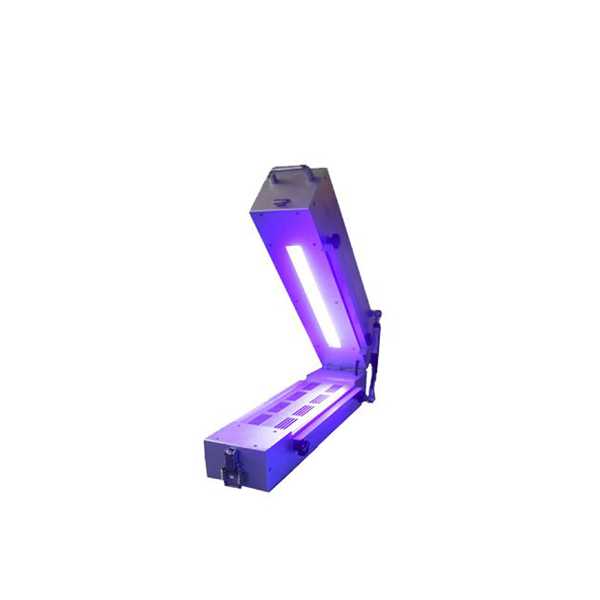

First, the UV light source

UV flexo printing requires an ultraviolet light source for each color set.

Different colors of UV flexo inks have different abilities to absorb ultraviolet light.

It is necessary to distribute the power of the UV lamp according to different colors

to ensure reasonable drying of the UV inks of various colors and save energy.

At the same time, attention should be paid to the aging of the UV light source,

and the UV lamp should be replaced in time to prevent the curing from being

incomplete and causing adhesion.

Second, the rubber roller

The rubber roller must be resistant to UV ink.

The rubber roller usually used is usually made of EPDM rubber

(ethylene propylene diene monomer) or silicone rubber.

Third, anilox roller

When using a UV flexo ink, the mesh angle of the anilox roller is preferably 30 or 60.

Fourth, the plate

Although the flexographic printing plate used can basically be used for UV flexo printing inks,

it is better to use a plate with better anti-UV ink properties, such as DuPont's UVP-67 open plate.

Five, additives

There are three main additives commonly used in UV flexo inks, namely UV reactive diluent,

UV curing accelerator and UV ink cleaning agent.

Sixth, storage

UV flexo inks should be stored in strict protection from light and heat.

The storage temperature should be controlled at 5 °C ~ 30 °C, and the

storage shelf life is generally half a year.

Seven, ink viscosity

UV flexo inks use a slightly larger viscosity than water-based inks or solvent-based flexo inks.

They range from 200 to 500 CPS.

Eight, security protection

At present, there are two main precautions, one is the harm of ultraviolet

radiation source to the human body, and the other is the harm of UV ink to the human body.